During exhibition planning one of the hardest decisions is what to leave out. The exhibition about prosthetic limbs, Reconstructing Lives, at the National War Museum is no different. This will display a wide variety of prosthetic limbs, but will not explain how they came to be designed and made. National Museums Scotland has recently been donated a wonderful collection showing the development of prosthetic hands in Edinburgh at the Princess Margaret Orthopaedic Hospital and later by the NHS research team. Some examples of their pioneering technological work can be seen in the Shaping our World gallery at the National Museum of Scotland, including the world’s first arm with electrically powered hand, elbow and shoulder, the Edinburgh Modular Arm System (EMAS). Also in this collection is a set of material used in the production of wonderfully life-like cosmetic hands by a technique perfected in Edinburgh.

So, how did they make these cosmetic prosthetic hands?

The fingers were cast in foam with copper wire down the middle of the fingers so they could be bent to different shapes and posed. The technician kindly cast a foam hand left unfinished in its mould especially for the museum.

The finished foam hands are human in shape, but not exactly skin coloured.

To make the outer coatings, or gloves, for these hands they found a volunteer with the right size and shape hands and coated their hand and arm in moulding plastic. Pulling this off tore the hair out of the model’s arm. I am assured the detail of the final product was better because of those hairs stuck in the mould.

A silicone mould was taken from the master hand, smooth on the outside, but with all the details of the model’s skin, and of those hair roots, on the inside. Lots of these moulds could be made from one resin hand cast.

A resin cast was taken from this mould – these master casts were stored in a library of dozens of boxes.

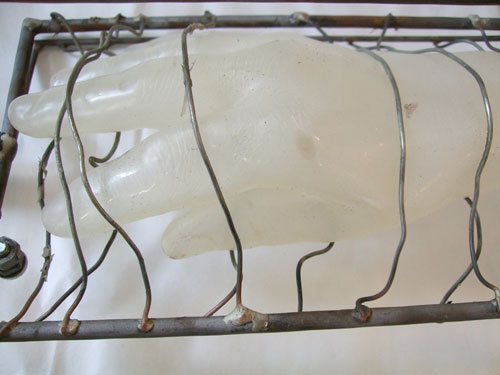

The mould was mounted in a wire framework to keep it in shape. This was mounted on a motor and rotated while the final cosmetic glove was cast inside it in layers of different coloured silicone. Some of these used up to 25 layers of different colours to match the translucency and depth of human skin, though in production the manufacturing was refined down to four layers.

Examples of the finished product are in the Shaping our World gallery.