National Museums Scotland houses the Turkey Red collection, which comprises around 40,000 items.

‘Turkey Red’ is a complex dying process that produces a bright, fast red. Its origins began in the East and from the late 18th century development grew in the West. The Scottish Turkey Red industry, based in the Vale of Leven, Dunbartonshire, thrived until competition from other producers and manufacture of cheaper materials forced the companies to merge, forming the United Turkey Red Company Limited in 1898. Production continued until 1961, when the final factory closed.

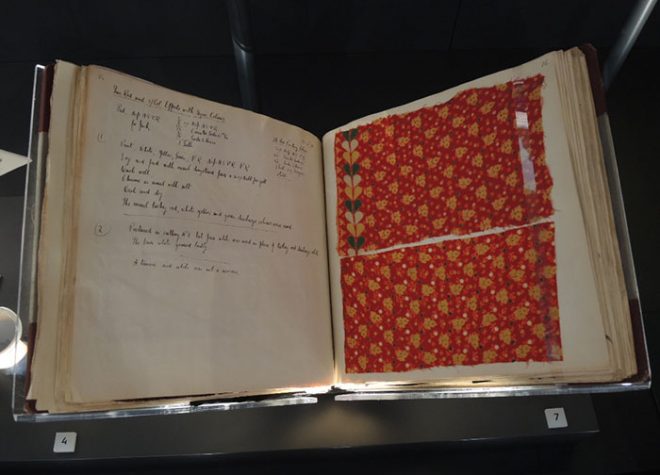

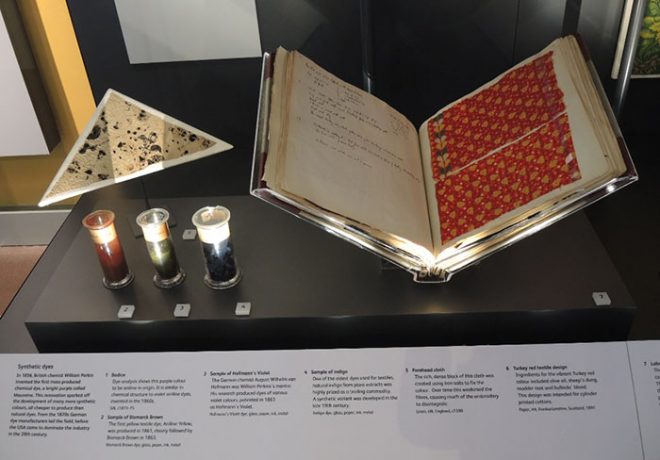

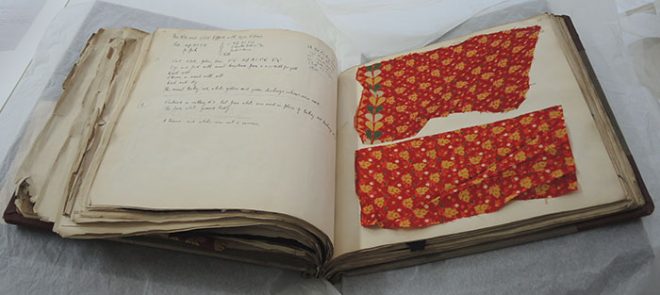

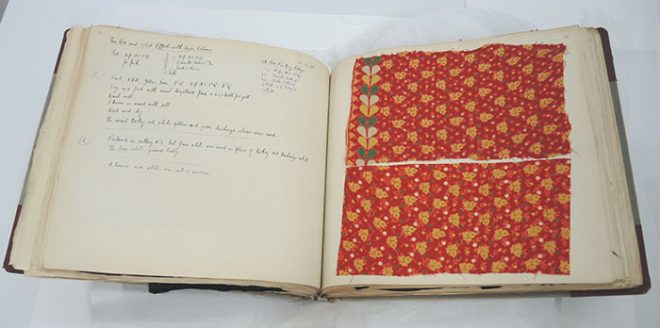

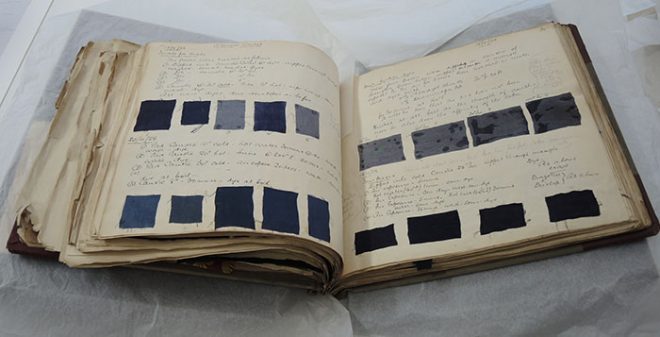

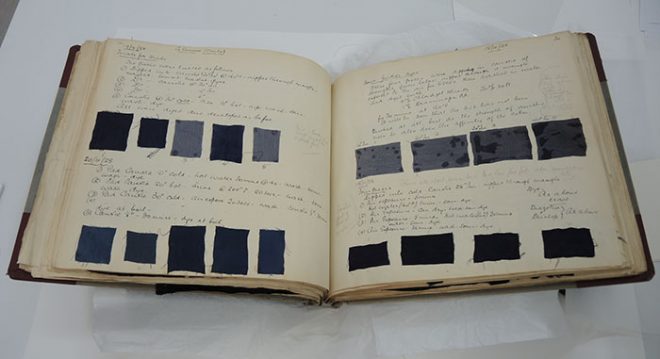

This laboratory book dates from 1928-1929 and records experiments on dyes. The recordings are noted in handwritten ink with printed cotton textile samples attached.

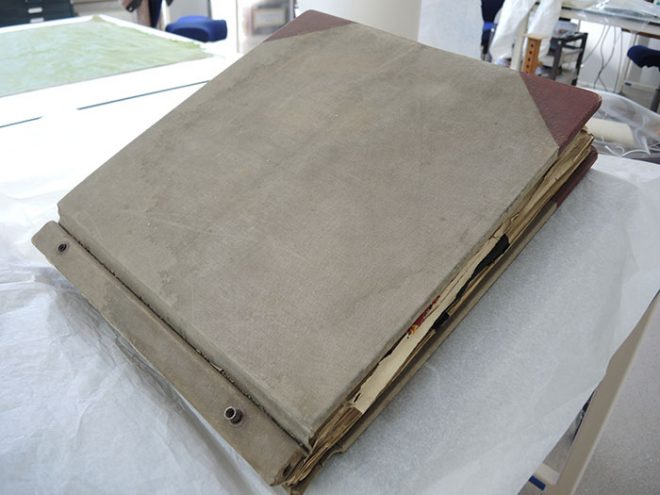

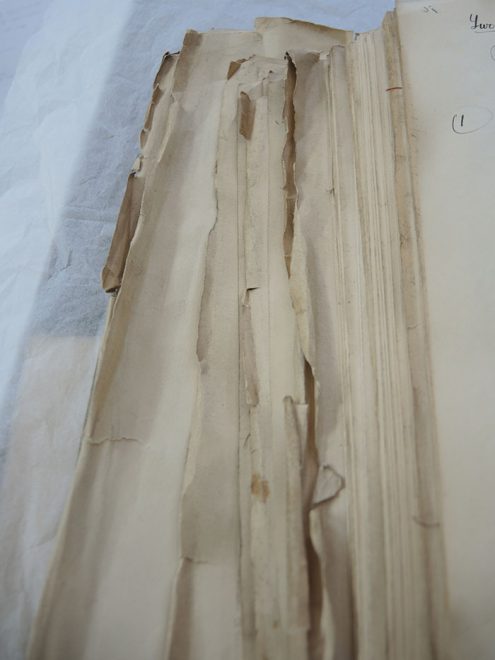

The laboratory book has a post-binding structure which allows for easy insertion or removal of the pages. The fabric, leather and card cover encases cream wove papers of differing sizes. The simple nature of the binding and repeated handling of the pages over the years has caused structural damage to the pages in the form of dirt, creases and tears.

The book is cumbersome and didn’t close very well due to the insertion of loose pages, many of which contained no annotations or textile samples. They were therefore removed and stored separately.

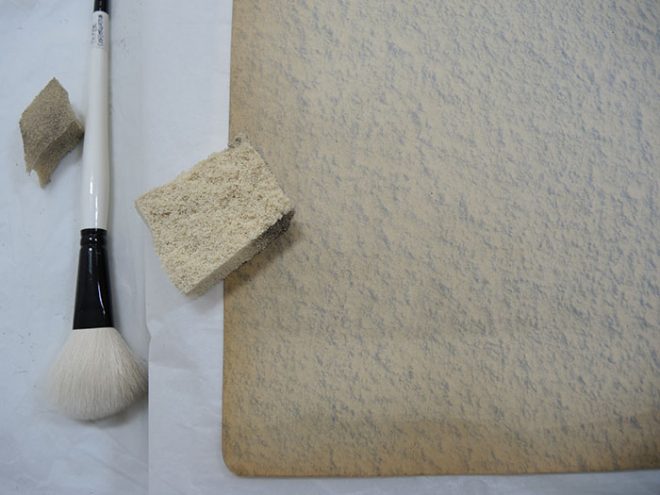

After photographing and writing a report on its condition, I began surface cleaning the laboratory book. I worked from front to back and interleaved a sheet of acid free tissue under each page as it was treated, to avoid any transfer of dirt to neighbouring pages.

The photograph below shows the tools I used. The latex chemical sponge shown on the left is good at removing loose surface dirt. More engrained dirt was removed with a conservation eraser. The lighter band near the bottom of the page shows where surface cleaning had commenced.

After surface cleaning, tears along the edges were repaired. Japanese tissue paper is the preferred support for repairing tears as it is lightweight, with a complementary tone, and is strong due to its long fibres. Usually we favour an aqueous adhesive called wheat starch paste, which is widely used in paper conservation but takes time to dry, and because of the amount of tears present on the pages and the 3D nature of the book, I needed to find a quicker treatment method.

I therefore used a re-moistenable tissue made from Japanese tissue and a combination of wheat starch paste and methyl cellulose (another type of conservation adhesive). The tissue was pre-prepared with the adhesive and left to dry. The desired size of repair was then cut from the prepared tissue, re-activated with moisture and dried immediately with a heated spatula on low heat, which made the process quicker.

To further improve the overall aesthetic appearance of the laboratory book, heavily crumpled edges were lightly humidified to relax them, and then pressed under light weight to reduce the deformations.

Some pages within the book had a high degree of structural damage, so even after surface cleaning, tear repairs and pressing, the pages still appeared damaged and unsightly. To reduce this, a sheet of archival quality paper was toned with watercolour to blend in with the book pages and inserted among them, thereby obscuring the most damaged pages and also preventing the exposed edges curling.

Two pages were chosen for display, one to be shown first and one for rotation in order to rest the light-sensitive media and dyed fabric. These pages were given greater conservation attention, with further surface cleaning and conservation of the fabric samples.

Most of the textile samples are attached to the pages of the book with dabs of adhesive. Over time, this adhesive has aged, losing much of its strength, and therefore many fabric samples are loose and detaching. The page to be displayed first had two large, creased fabric swatches and these were treated by a textile conservator in a similar manner to the paper: lightly humidified and pressed to remove their creases.

For transport to the Museum, a folder was made to protect the book and a sheet of inert polyester (Melinex) placed over the display page to hold the fabric samples in place.

The total conservation time spent on this book was 62 hours.

You can find the Turkey Red laboratory book on display in the new Fashion and Style gallery at the National Museum of Scotland. Mount makers Plowden & Smith made the acrylic book cradle.