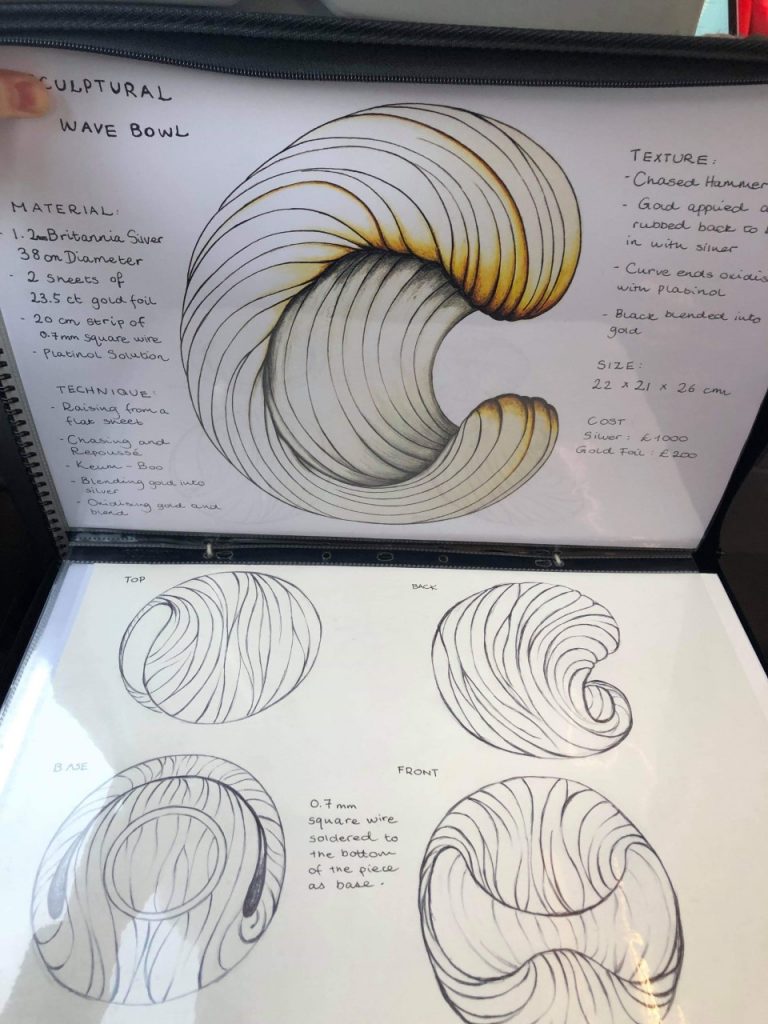

Silversmith Jessica Jue designed and created Wave, a stunning sculptural centerpiece inspired by water. Commissioned by National Museums Scotland and the P&O Makower Charitable Trust, Jessica explores her design approach and the skills and techniques she used to harness the movement of water through silver.

The opportunity to work with a museum on a commissioned piece has been an incredible experience. With a flexible and experimentative brief, I was excited to create a design of my own choice, as it meant I could try new techniques and develop my skills. I have always wanted to combine different metals and was able to explore the Korean gold fusing technique of Keum-Boo for this piece.

For the design, I took inspiration from the form of a crashing wave. I have been fascinated by water and its fluidity for as long as I can remember, and this was my chance to make a statement piece inspired by its powerful movements.

Raising and forming

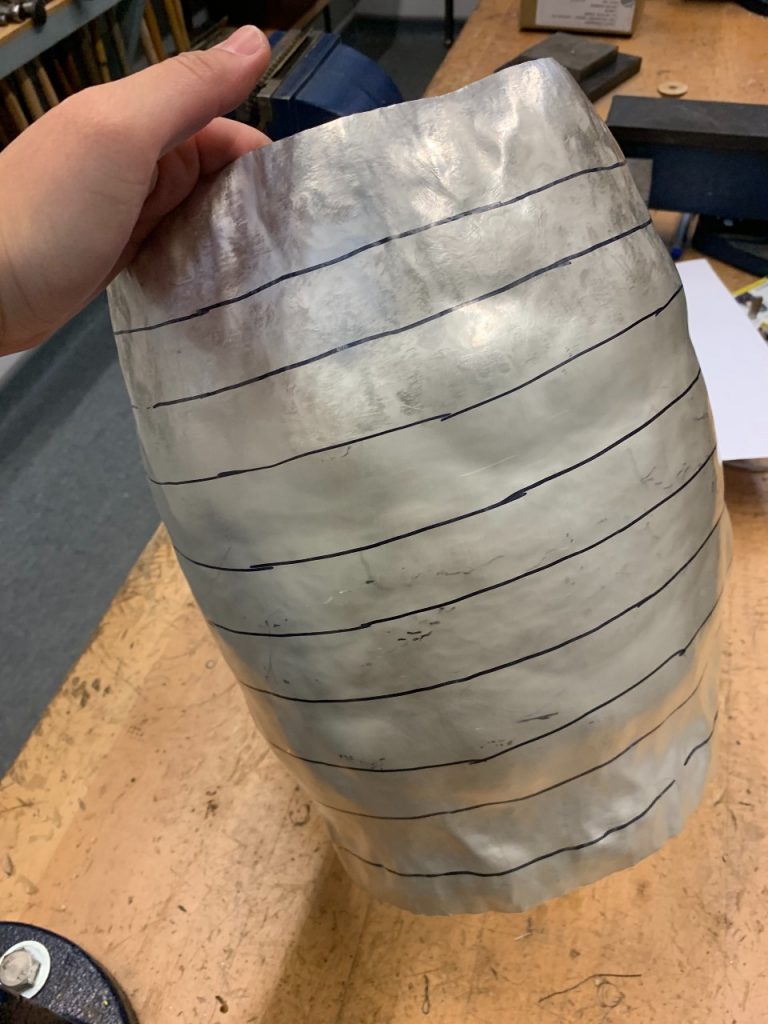

It might sound surprising, but the piece started off as a large flat sheet of silver. To create a rounded form, I worked the sheet into a cylindrical shape, which I soldered along the seam in order to prepare it for ‘raising’ (the process of hammering a flat sheet of metal into a form).

The aim of this was to eventually create a rounded donut shape that would later become the wave. Once I had a cylindrical shape to work with, I marked lines out on the piece horizontally in order to raise and shape it into a more rounded form (creating a kind of belly) with tapered raised ends that would lead to the desired donut shape.

This was one of the most challenging parts of the process. The scale was larger than I was used to working with and was also very heavy, which meant holding and positioning the piece in place was tricky.

An important part of the process, which was even more time consuming than the actual making, was the continuous planning and decision-making. I had to stop every so often to assess the piece and compare it to the original design using a template I’d made. Having said that, I also didn’t want to ignore the beautiful way in which the metal was naturally shifting as I worked it.

Through a process of hammering, following the lines I made, and softening the metal with heat (called annealing), I was able to the raise the ends of the cylinder inwards creating a smooth, rounded shape, ready for the next stage. With the donut form achieved, I cut the seam open and then marked out lines for raising the open edges inwards to create the curl of the wave.

Chasing and repousse

I used a technique which has started to become a signature style of mine: ‘chasing and repousse’. This is a traditional metalworking technique where we create resistance so that the surface of the metal can be worked on and given texture and dimension, but without punching all the way through.

In simple terms, ‘repousse’ means to ‘push forward’ or ‘push up’. It refers to the metal being raised by hammering from the back to create dimension in front. ‘Chasing’ then outlines the pushed forward designs by pushing back around their edges to help define them. I love chasing as it doesn’t just add to the surface of my pieces, but because of how deep I can push the metal, it has become one of my key methods of forming a shape.

To create that resistance, I filled the metal form with pitch to allow me to hammer heavy relief onto the piece. Chaser’s pitch is a thermal adhesive that holds a metal piece while it is being hammered out for chasing and repousse. You heat it up, pour it where it needs to go and then it solidifies in place. To fill the wave with pitch, I built a wall of masking tape around the piece so when the hot pitch was poured in none of it leaked out.

The piece took months to chase over. One reason for this was that the pitch had to be emptied after every round of chasing because it needed to be annealed (heated and softened) as the metal hardens in the process. In total, the pitch was emptied and put back in at least 20 times!

An unexpected aspect of chasing a piece of this scale was that the silver almost developed a life of its own. The chasing would shift and warp the form in unexpected directions. I had to decide whether to stick to the original design or let the natural behavior of the metal take it somewhere else.

The chasing hammer I use the most has been with me for three years. Silversmiths’ tools tend to be with us for life and I always have a feeling of comfort and familiarity when I pick up my hammers. I even made my chasing punches myself. They are used for tapping the decorations and relief onto silver pieces with a hammer. I was taught how to forge a punch when I was in Shetland. I was there for a master class with Rod Kelly and I made these punches the minute I got back to my workshop and have held on to them ever since.

Keum-Boo

The final stage of the making was to fuse gold foil on to the surface of the piece. This process is called Keum-Boo, which is the ancient Korean technique used to fuse thin sheets of pure gold onto silver using heat and pressure.

When using sterling silver sheet as I do, a layer of pure silver must first be brought to the surface. This is done through heating the silver multiple times (known as ‘depletion’). The 24ct gold foil is then cut into shape and laid on top of the silver. A combination of the heat and pressure applied causes an exchange of electrons between the metals and creates a strong and permanent bond.

Finished piece

The opportunity to work with a museum on a commissioned piece was an incredible experience. As a graduate, it was great for me to understand how a formal commissioning process is followed through. I have learned a lot from my creative discussions with the commissioner and curator, undertaking research, expanding my ideas into something tangible and presenting them in the form of sketches or models.

In terms of making, it was a tremendous undertaking. I was able to improve on existing skills and adopted new techniques too. It is also such an honor to have a statement piece like this displayed in the National Museum of Scotland, knowing that it will be seen by so many visitors.

Jessica Jue graduated from Edinburgh College of Art in 2016 with an undergraduate degree in Jewellery and Silversmithing before completing a postgraduate residential course in silversmithing at Bishopsland Educational Trust.